The SAVRRS was created by myself and 5 other Mechanical Engineering Seniors at Arizona State University for our capstone project. The system is capable of repelling sharks from shorelines and other areas without doing any harm to the shark or humans around the area to make sure the coastline remains safe for humans as well as sharks. During this project, we came up with the idea, designed the concept, built the device and tested the device in order to verify that the system is in fact operational and achievable.

The first phase was brainstorming ideas and deciding on what we wanted to build throughout the 2 semester long project. We had lots of ideas, including an energy recovery system from drain water, space debris collection system and of course, the shark repellent system (a drone that is capable of repelling sharks from coastlines).

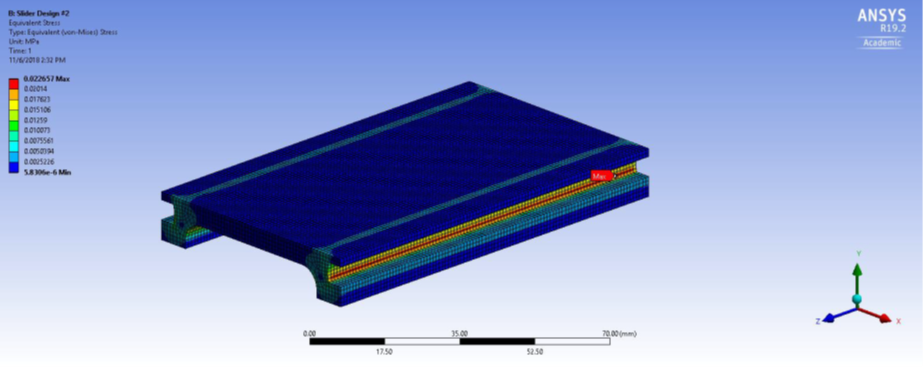

We then set about with preliminary designs and calculations to show that the design is in fact feasible. This was a lot of verifying that the system structure was sound with a high factor of safety where needed, verifying weight and lift capabilities of components we might use and calculations and drawings to ensure that the project was in fact feasible.

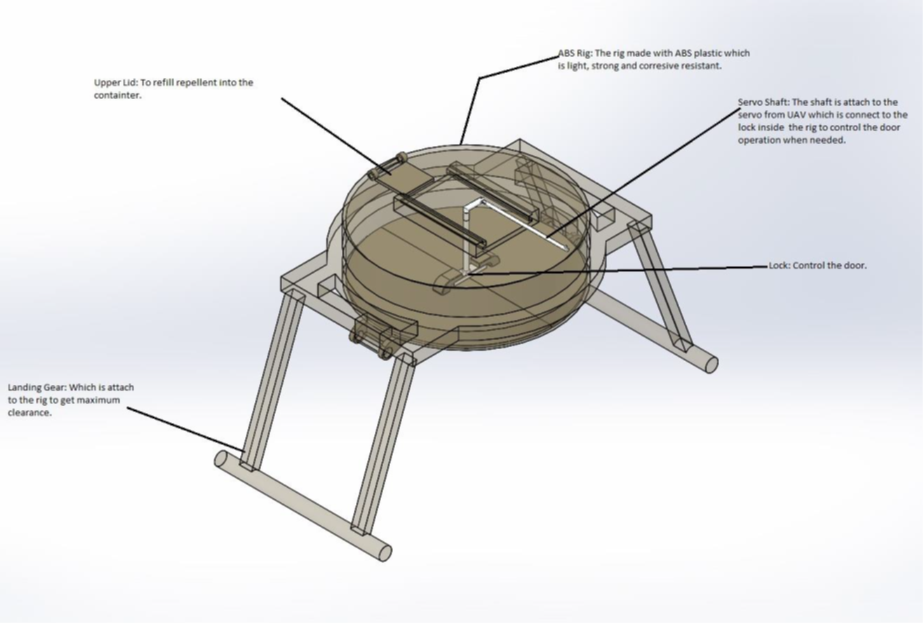

Using this initial knowledge, we set out to build virtual models to make sure that parts were compatible with each other and make sure that interferences and tolerances were accounted for. This meant a lot of CAD modelling and compiling to make sure that the design was in fact satisfactory.

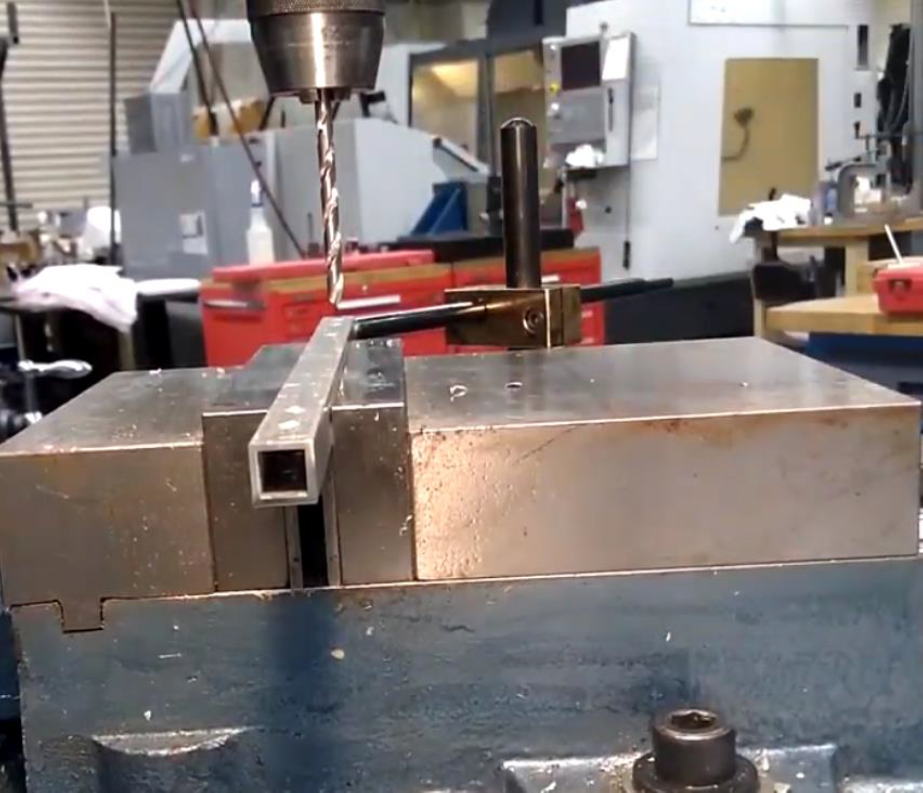

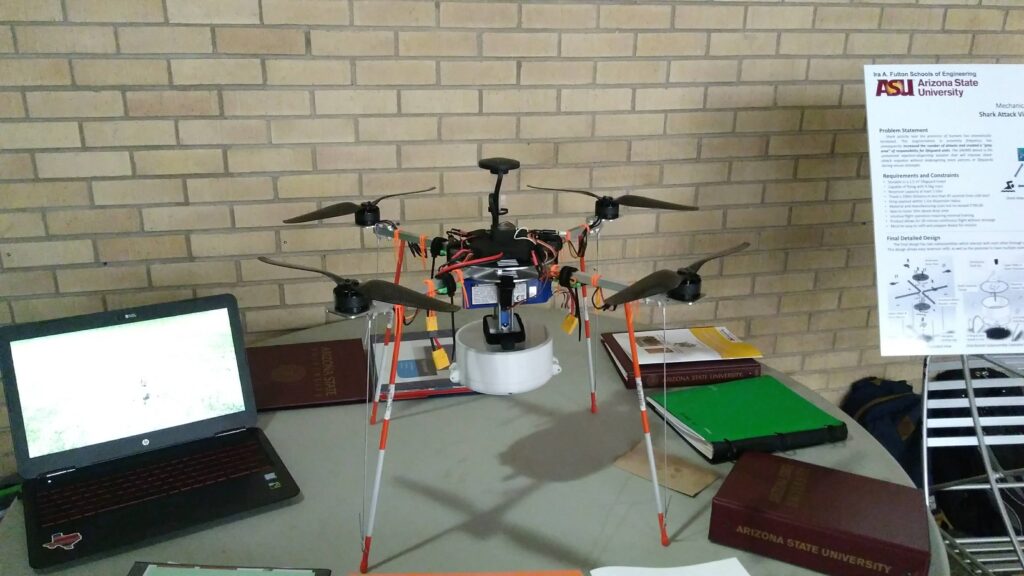

My most favorite part of the project comes next, manufacturing. We spent countless hours at the workshop getting our project together. We practiced milling, 3D printing, CNC machining, using various kinds of drills, saws and adhesion methods to make sure the device was ready for testing and demonstration.

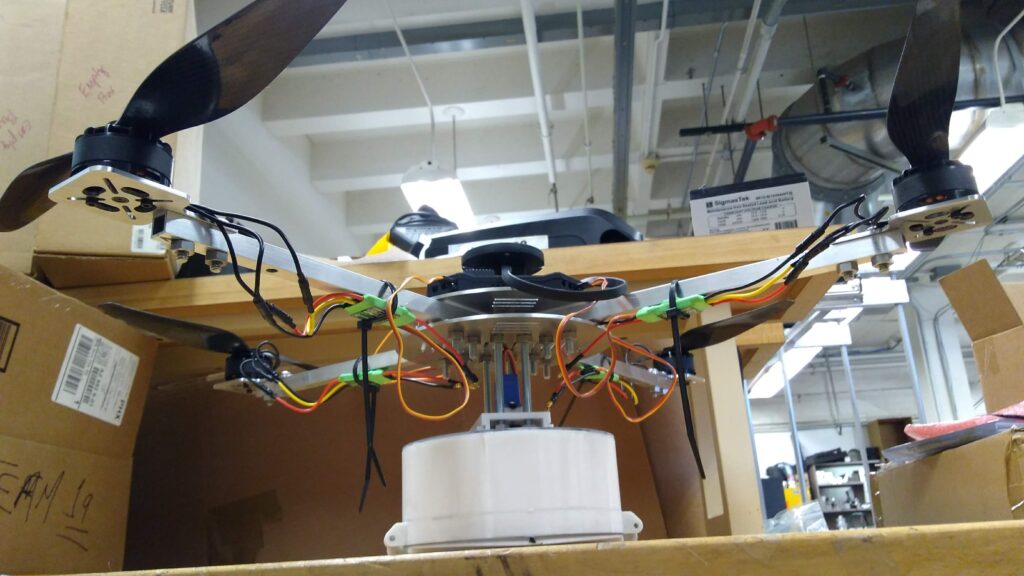

This of course led to perhaps the most underlooked phase in a lot of products, testing! Testing was done component-wise, system-wise and product-wise in a progressive manner to make sure that each component worked well as a system and each system worked well as a complete device. Testing included actuation testing, flight system testing, accuracy testing and power testing to name a few.

The final day of the class included a presentation to members of the engineering community, proof showing the product was functioning, project report and documents to show the process that was taken and a poster board showing the device we had developed and constructed.